Often, the use of metrology is included in designing and controlling manufacturing processes. Generally, metrology involves processing a product sample, measuring a relevant property, and adjusting the process to bring the next sample closer to the prescribed product specification.

Metrology demands a certain extent of precision, accuracy, and a strategic and technical understanding of a particular product to further align the next sample with its ideal specifications. CCPL has such capabilities, as we have one of the best metrology infrastructure setups. Our engineers and execution staff ensure the highest levels of process efficiency and effectiveness to ensure the objectives are met.

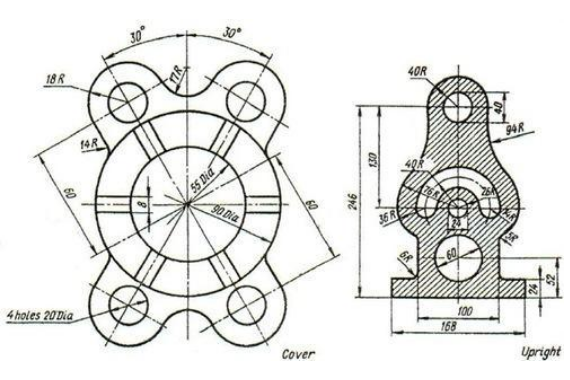

GDNT stands for Geometric Dimensioning and Tolerancing. It is a system to define and communicate engineering tolerances and relationships. GDNT uses symbolic language or engineering drawings alongside computer-generated 3D solid models that describe nominal geometry and the variation allowed. It also specifies the degree of precision and accuracy required on every controlled feature of the part.

At ccpl we hold the capability and maturity to handle such drawing demands. Our expertise helps customers understand and determine, the impact on costs as well as machinability